COATING DATA

DESCRIPTION:

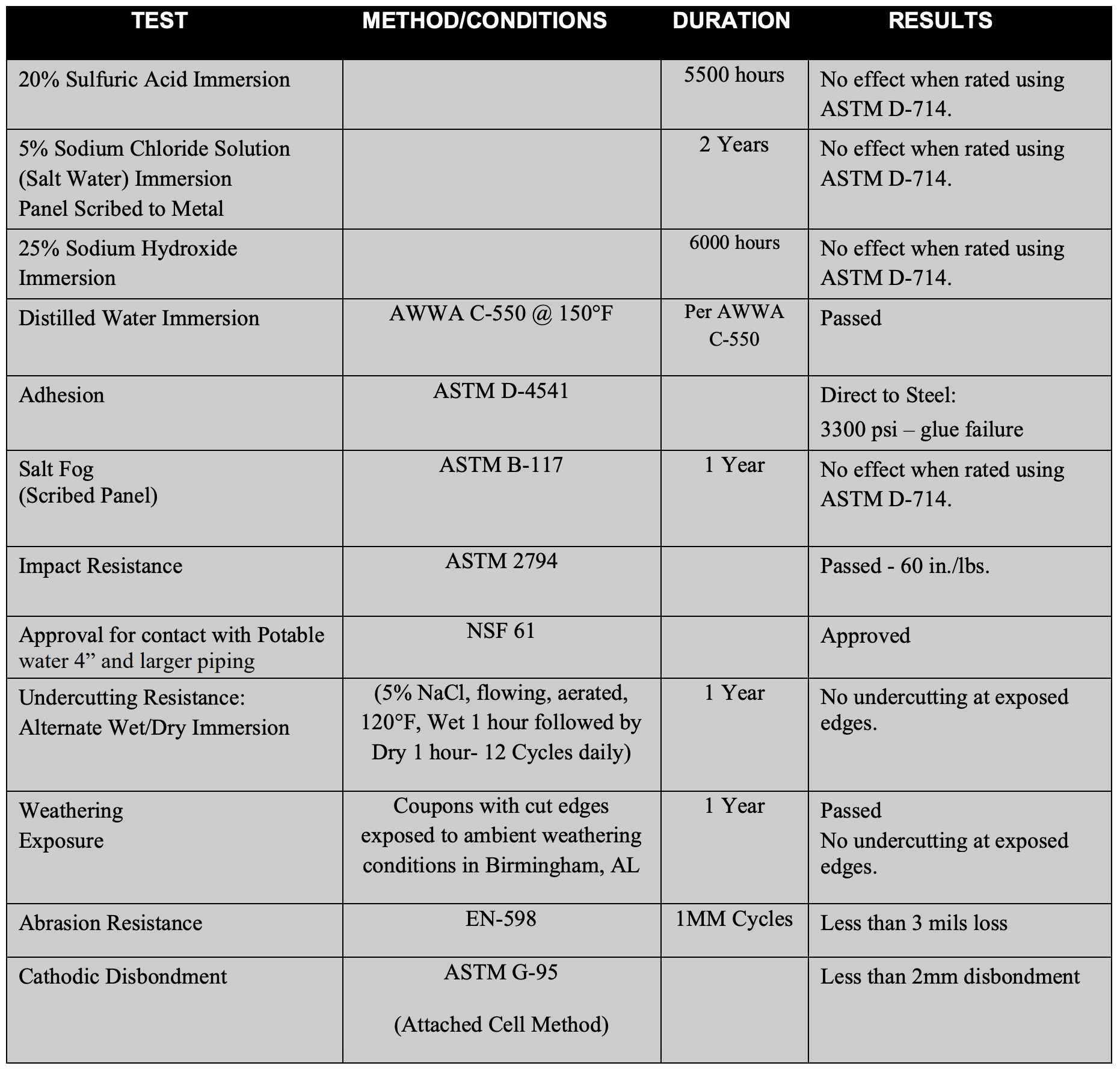

A two-component, high solids, chemically cured epoxy coating. Ceramapure™ PL90 Ceramic Epoxy is a unique and outstanding barrier coating formulated for the protection of ductile iron or steel pipe and fittings. Ceramapure PL90 may be used for service in wastewater or water with excellent abrasion and corrosion resistance. This product has been certified by the Water Quality Association to meet the requirements of NSF/ANSI International Standard 61 for potable water immersion service for pipe diameters of 4” and up. Ceramapure PL90 meets or exceeds the compliance standard for AWWA C-210.

* Tested on lined ductile iron pipe coupons after 4 years of outdoor exposure (Birmingham, AL).

PERFORMANCE

LIMITATIONS:

Do not use for immersion service above 120°F (49°C) or dry heat above 200°F (93°C).

SURFACE PREPARATION:

See suggested standard specification for ductile iron or steel (www.Ceramapure.com).

COVERAGE:

Theoretical— 1,476 ft2 per gallon at 1.0 mil dry film thickness.

DRY FILM THICKNESS:

Lining Ductile Iron: 40 mils nominal

Lining/Coating Steel: 20-25 mils. Multiple coats may be used if necessary.

APPLICATION DATA

BLEND RATIO:

One-part Ceramapure™ PL90 Ceramic Epoxy Activator to one-part Ceramapure® PL90 Ceramic Epoxy Base by volume. Power agitate until components are thoroughly mixed.

APPLICATION:

Certified Application Required.

THINNING:

None required. Clean equipment with K-1034 Reducer.

CLIMATE:

Use this product only if the substrate temperature and ambient air temperature is above 45°F and is expected not to decrease for at least two hours after application. Also, the substrate temperature must be 5°F above the dew point for a period of at least two hours after application to avoid condensation occurring on wet paint.

DRY TIME:

NON-POTABLE IMMERSION SERVICE—50°F or higher, 7 days with proper ventilation;

40°F-50°F, 14 days with proper ventilation.

POTABLE WATER IMMERSION—Allow 30 days cure.

SAFETY DATA:

See individual product label for safety and health data information. Individual Material Safety Data Sheets are available upon request.